|

The new beam will slide into the 6 inch gap between the iron frame and leaf spring. Temporary blocks widen the gap.

(Drain pipe had to go. The rag directs water to a bucket.)

|

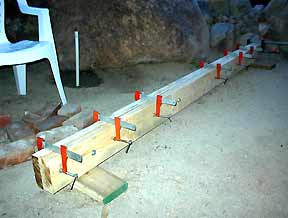

A sandwich of 2x6s & ½” ply, heavily glued, bolted and clamped. The 2x6s should have been clear (no knots) & age dried. Bolts & clamps should have gripped the edges.

|

The top ends were shaved & sanded so that rain would run off

rather then inward.

|

|

Recesses

are cut to fit the post connectors.

|

The

finished beam (tool handles & box trailer roof) are treated with 50/50

linseed oil & mineral spirits.

|

The beam is slid between the jacked-up iron frame & leaf

springs, against the wheel hubs, and positioned over the posts.

|

|

The post

connectors are inserted into place. Unseen aluminum flashing was laid along

the top of the beam between the trailer edges.

|

Steel plates have been placed beneath the contact points of the

iron frame.

The trailer & beam are then let down to rest entirely on the

2 posts. Nothing breaks.

(The trailer tongue is wedged firmly into place to prevent

sway.)

|